Blower

We design and manufacture new blowers for all kinds of applications in line with current industry standards. Creativity and innovation are inbuilt in our Shobha Engineers culture.

Blower casings are made up of MS, SS, PP & PVC materials depending upon the application. Impellers are dynamically balanced and tested as per Indian Standard 4894. The entire life cycle of the blower will be taken care of by the Shobha Engineers expert team. For the benefit of the customer, we also perform servicing of existing blowers at the customer end.

Ranges: 250 m3/hr to 105000 m3/hr or 1hp to 250 hp

Types of Blowers We Make:

- Positive Displacement Blowers

- Rotary Lobe Blowers

- Helical Screw Blowers

- Centrifugal Blowers

- Multistage Centrifugal Blowers

- High-Speed Blowers

- Regenerative Blowers

- DWD Blower for Drier

- BB10 Blowers for Rice Mills

With Different Type of MOC:

- MS Blower

- SS Blower

- PP & FRP Blower

Dust Collection System

.jpg)

Customized Dust Collection System (DCS)/Fume Extraction System is an air pollution control equipment that draws harmful particulate matter/fumes released from a manufacturing process into the work environment.

It then filters/purifies the hazardous fine dust/fumes, fine contaminant particulate matter, and finally releases clean air to the atmosphere. We design and manufacture new Dust Collection Systems.

Our DCS is suitable for process-based industries such as cement, sugar, power plants, etc. We supply spares and undertake DCS repairing/servicing work at the customer's end. We are experts in Turnkey system implementation.

We successfully handle both filter bag type dust collectors and cartridge type dust collectors. We deliver DCS for MDC and APH applications suitable for boilers.

Applications:

- Robotic welding zone application

- Mining industries

- Power plant application suitable for coal and bagasse

- Plastic injection molding application

- Chemical plant application

Scrubber

Scrubber (Dry & Wet) is an air pollution control device. It removes the particulate matter or gases from an industrial exhaust or flue gas stream.

Shobha Engineers has engineered scrubbers and is involved in the design, manufacture, and servicing of scrubbers in line with industry requirements for more than a decade.

With Different Types of Material of Construction (MOC):

- MS (Mild Steel)

- SS (Stainless Steel)

- MS+FRP (Mild Steel + Fiberglass Reinforced Plastic)

- PVC (Polyvinyl Chloride)

Our scrubbers are crafted with precision, offering versatility through various Materials of Construction (MOC). Clients can choose from different MOC options to suit their specific needs, ensuring optimal performance and longevity. Whether it's addressing particulate matter or tackling complex gas emissions, our scrubbers are engineered to provide effective solutions for diverse industrial applications.

.jpeg)

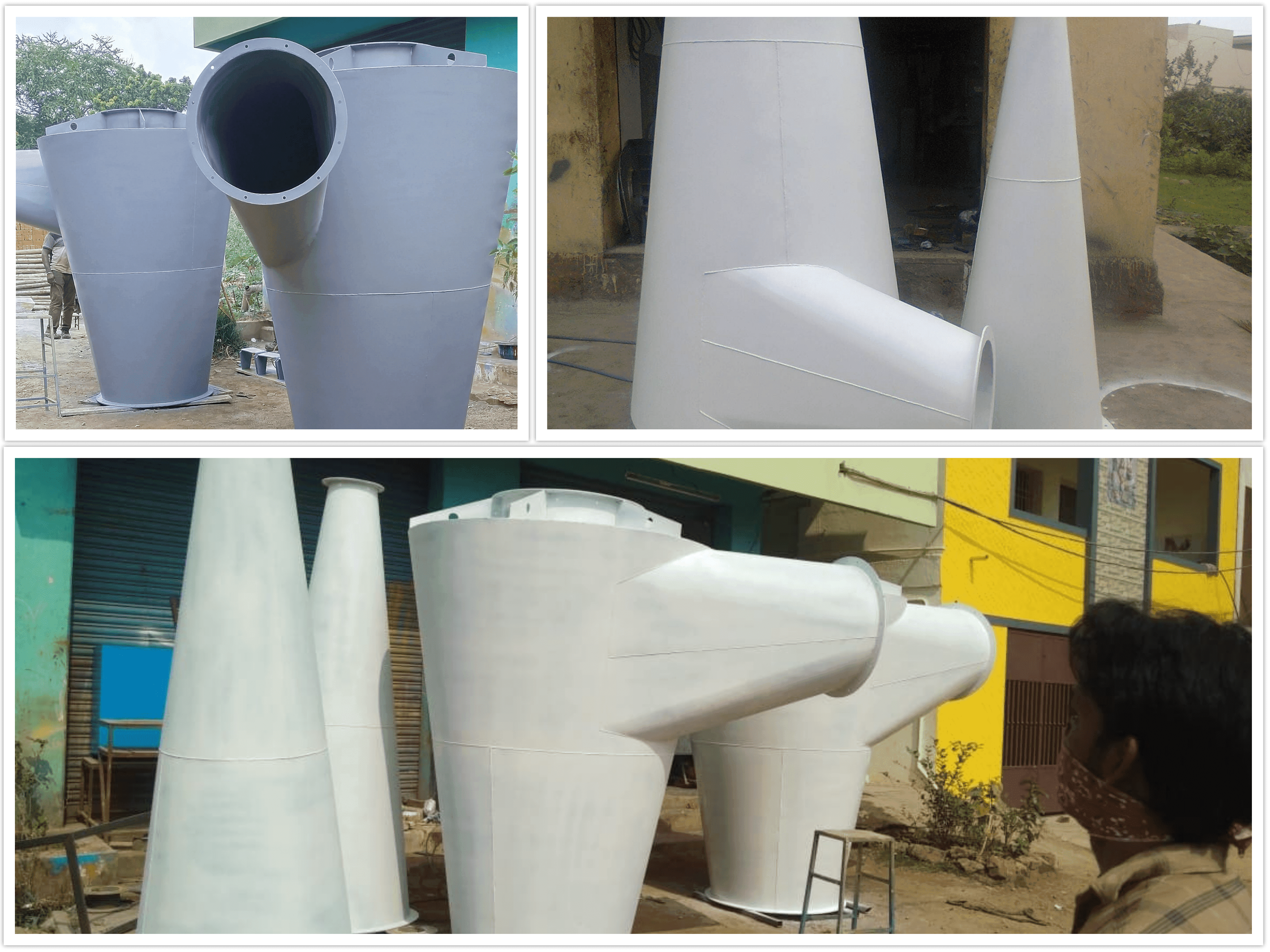

Cyclone Separator

Cyclone separator is a separation device that uses the principle of inertia to remove the particles of matter from exhaust. We handle single stage and multistage cyclone separator for servicing with at most priority and do Turn-key system implementation as well. We do care of these equipments till its life cycle.

Applications Include:

- Industrial application

- Flour mill application

- Quarry application for sand classification

At Shobha Engineering, we prioritize the servicing of both single stage and multistage cyclone separators, implementing turn-key systems with utmost care. Our commitment extends throughout the life cycle of these equipments. The applications of our cyclone separators span across various industries, including industrial settings, flour mills, and quarries for efficient particle removal and sand classification.

Chimney

The self-supported metallic chimney is the most preferred system to exhaust the hot gases to the environment, preventing the inhalation of harmful substances by living creatures. At Shobha Engineers, we specialize in delivering optimal and accurate chimney system solutions for various industrial applications. Our expertise extends to the construction of chimneys using materials such as MS, SS, and other non-metal PVC.

Civil construction required for chimney installation, such as chimney foundation and foundation bolts, is seamlessly handled by the Shobha Engineers team. Our dedicated civil team excels in managing all aspects of chimney installations, ensuring a hassle-free experience for our clients. From the foundation work to the final setup, we take care of the entire package, guaranteeing a reliable and efficient chimney installation.

Ranges: Diameter: 250 to 5000 mm, Height: 10 m to 100 m

Shobha Engineers stands committed to providing state-of-the-art chimney solutions that prioritize environmental safety and industrial efficiency. Our chimneys, available in a range of diameters and heights, are designed to meet the diverse needs of our clients across various industries.

Ducting

Shobha Engineers excels in providing expertly designed ducting systems tailored to meet the demands of diverse industrial applications. Our offerings include Circular, Square, Rectangular, and elliptical cross-section ducts, constructed from materials such as MS, SS, and GI. We take pride in conducting efficient duct erection and implementation activities, ensuring on-time delivery, a key factor in our continued success.

- Round Type

- Square Type

- Rectangular Type

- Elliptical Type

- Spiral Type

At Shobha Engineers, we offer a comprehensive range of ducting solutions, including insulation services. Our commitment to quality and timely delivery sets us apart as a reliable partner for all your ducting needs.

Painting Booth

Shobha Engineers offers a diverse range of automated paint booths tailored to meet the unique requirements of our customers. Whether it's manual or automatic paint booths, we provide comprehensive solutions with a wide array of equipment for various industrial applications. Our team excels in delivering turn-key solutions for both manual and automatic paint booths, ensuring seamless integration into your operations.

The paint booth solutions provided by Shobha Engineers are designed to be self-reliant, offering efficiency and precision in the painting process. We understand the importance of meeting industry standards and ensuring optimal performance for every application.

Powder Coating Plant | Oven

Shobha Engineers specializes in the turn-key implementation of automatic powder coating plants, providing a comprehensive solution designed and manufactured by our skilled team. Additionally, we offer manual painting solutions for low-cost operations, ensuring an optimized and efficient process overseen by the experienced engineers at Shobha.

Whether you are looking for an automated powder coating plant or a manual painting solution, Shobha Engineers is committed to delivering high-quality systems that meet your specific requirements. Our expertise spans across various applications, and we ensure that our solutions contribute to the success of your operations.

ETP

Shobha Engineers is committed to environmental sustainability, caring not only for clean air but also for clean water solutions. We specialize in servicing effluent water treatment plants, offering component replacement and revamping services. Our expertise extends to the erection and commissioning of ETP systems throughout India.

Additionally, we supply various components, including pipelines, fabrication of vessels, temporary sheds, etc. Our dedicated team ensures the efficient and reliable functioning of ETP systems, contributing to the preservation of clean water for the Earth.

Shobha Engineers takes pride in its commitment to environmental stewardship through the efficient management of effluent water. Our dedicated team not only provides reliable maintenance and component replacement for existing ETP systems but also spearheads the erection and commissioning of new systems across diverse locations in India.

PEB Shed (Pre-Fabricated Structure)

Shobha Engineers takes pride in its expertise in designing, manufacturing, and erecting pre-fabricated storage and warehouse sheds. Our versatile solutions cater to a range of applications, including storage for coal, grains, sand, and various factory requirements. We collaborate with experienced structural designers, fabrication experts, and skilled erection teams to ensure the highest quality and durability in our pre-fabricated structures.

Our commitment to excellence extends from the initial design phase through the manufacturing process to the final erection of PEB sheds. Whether it's a warehouse, factory shed, or storage facility, we tailor our pre-fabricated structures to meet the specific needs of our clients, emphasizing both functionality and aesthetics. Shobha Engineers aims to provide turn-key solutions, ensuring a seamless experience for our clients in the construction of durable and efficient pre-fabricated structures.

With a focus on innovation and sustainability, our PEB sheds are designed to withstand diverse environmental conditions, providing a robust and long-lasting solution for your storage and warehouse needs. Shobha Engineers stands as a reliable partner for clients seeking top-notch pre-fabricated structures that combine engineering excellence with practical functionality.

Heavy Vessel Fabrication

Shobha Engineers is committed to excellence in the fabrication of heavy vessels, meeting the specific needs of chemical industries, paper mills, boilers, and distillery applications. Our fabrication capabilities range from 1 meter to 3 meters in diameter, with lengths spanning from 1 meter to 5 meters. Upholding our own workshop principles, our skilled fabrication team ensures precision, quality, and reliability in every project, adhering to the highest industry standards.

With a legacy of craftsmanship and a commitment to technological innovation, Shobha Engineers stands as a leader in heavy vessel fabrication. Our experienced team combines traditional expertise with modern manufacturing techniques to deliver vessels of superior quality. From intricate chemical processes to the demanding requirements of paper mills and distilleries, we tailor our fabrication approach to meet the unique needs of each industry.

At Shobha Engineers, we view heavy vessel fabrication not just as a process but as a form of artistry. Each vessel, carefully crafted and precision-engineered, is a testament to our dedication to excellence. Our workshop principles emphasize attention to detail, ensuring that every project, whether for a 7-star hotel or an industrial application, receives the same level of meticulous care and expertise.

Polishing

Shobha Engineers operates a specialized polishing unit dedicated to enhancing the aesthetics of various utensils destined for exclusive use in 7-star hotels. Our commitment to quality extends to employing diverse polishing methods that cater to the distinct preferences of our valued customers. We take pride in executing a variety of polishing techniques on a regular basis, ensuring a consistent and impeccable finish.

Transforming utensils into exquisite pieces suitable for the finest establishments is an art perfected at Shobha Engineers. Our polishing team utilizes different methods to achieve perfection, meeting the discerning standards of 7-star hotels. From routine polishing tasks to special projects, we deliver superior results, showcasing our dedication to craftsmanship and customer satisfaction.

HDP Works

Shobha Engineers has a separate team for HDP works. We can use HDP components in place of mild steel components or other metal components.

At Shobha Engineers, our dedicated team specializes in HDP (High-Density Polyethylene) works, offering a versatile alternative to traditional materials. Whether substituting HDP components for mild steel or other metals, our team is well-versed in leveraging the unique properties of high-density polyethylene to meet specific project requirements.

Shobha Engineers takes pride in harnessing the potential of HDP in various applications. Our skilled team ensures that HDP components not only provide robust solutions but also contribute to sustainable and efficient designs. With our expertise, we offer clients the flexibility to explore innovative approaches using High-Density Polyethylene for their projects.

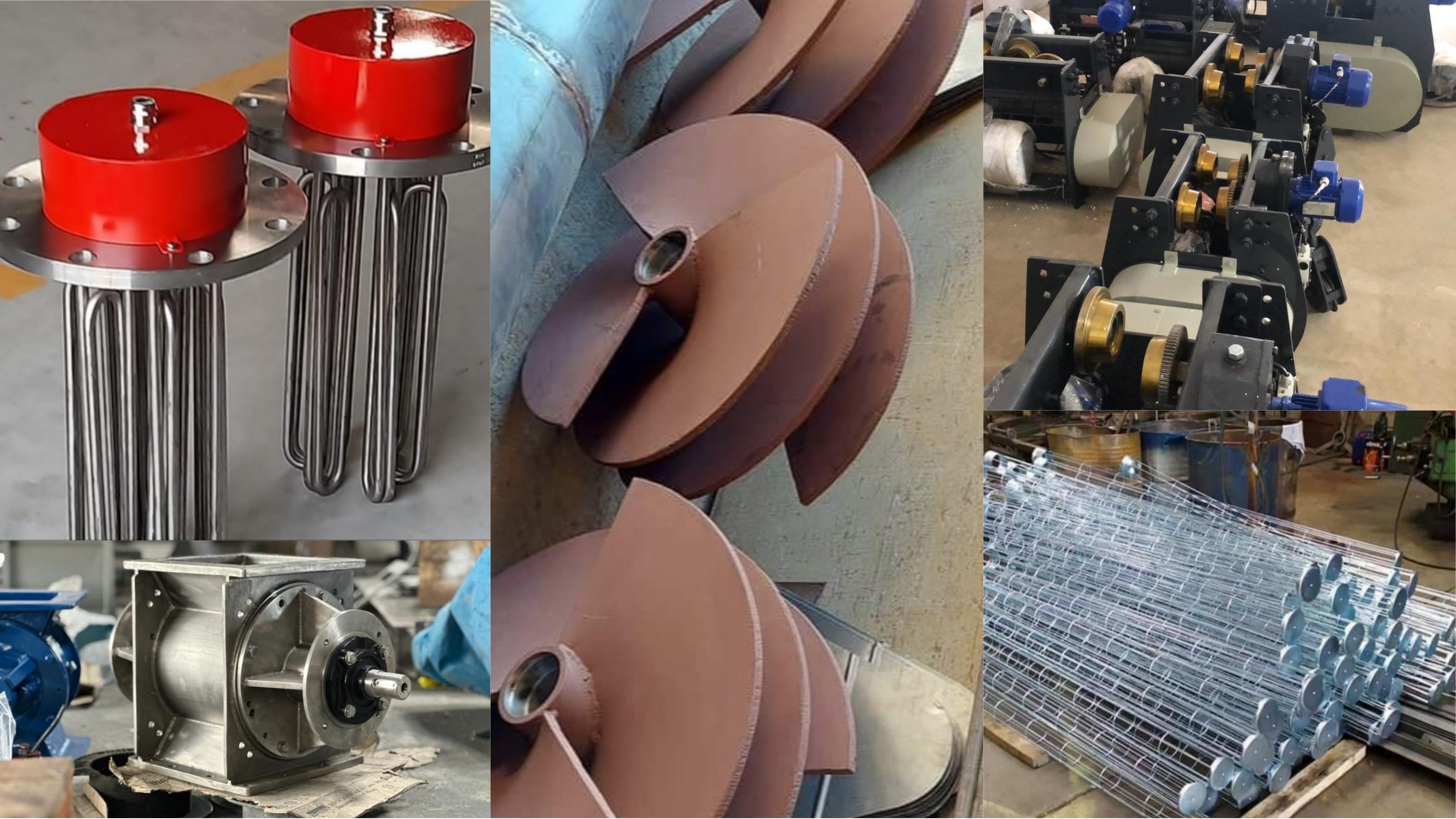

Spares

Shobha Engineers takes pride in being your comprehensive source for industrial spares, offering a diverse range of components to support the efficient functioning of various equipment. From essential parts like impellers and cages to specialized items such as RAVs, damper motors, and screw conveyors, we provide a comprehensive selection of spares. Our offerings extend to critical components like belt conveyors, heaters, pulse jet valves, electrical panels, dampers, filter cartridges, painting guns, and more.

We not only supply spares but also engage in refurbishment activities related to the mentioned equipment. Shobha Engineers stands as a reliable partner, ready to fulfill your industry's spare part needs. Whether it's a single component replacement or a comprehensive refurbishment project, we have the expertise and commitment to ensure the seamless operation of your industrial equipment.